The commissioning of the stamping machine for railroad wheels at the Czech production plant BONATRANS was successfully completed. We would like to thank our customer and partner ZDAS as well as BONATRANS for the good cooperation, which enabled us to deliver and commission the machine faster than planned. All in all, the machine could be put into operation two months earlier.

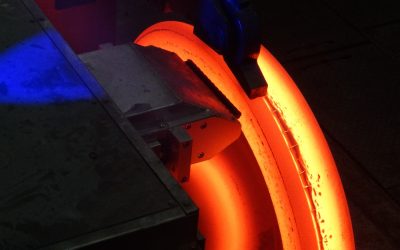

The machine stamps hot railroad wheels at up to 1,100 degrees Celsius. It is equipped with three fast travel axes and a robust WheSt-14 stamping head that can hold up to 14 different characters. It was particularly important to achieve the fastest possible stamping in order to shorten the cycle time in production. This was achieved by our special hydraulic stamping head, which makes it possible to control all stamping symbols almost simultaneously and to complete the entire stamping process within a very short time. The stamping machine runs continuously in several shifts without significant downtimes and thus enables the production of railroad wheels to be increased further.