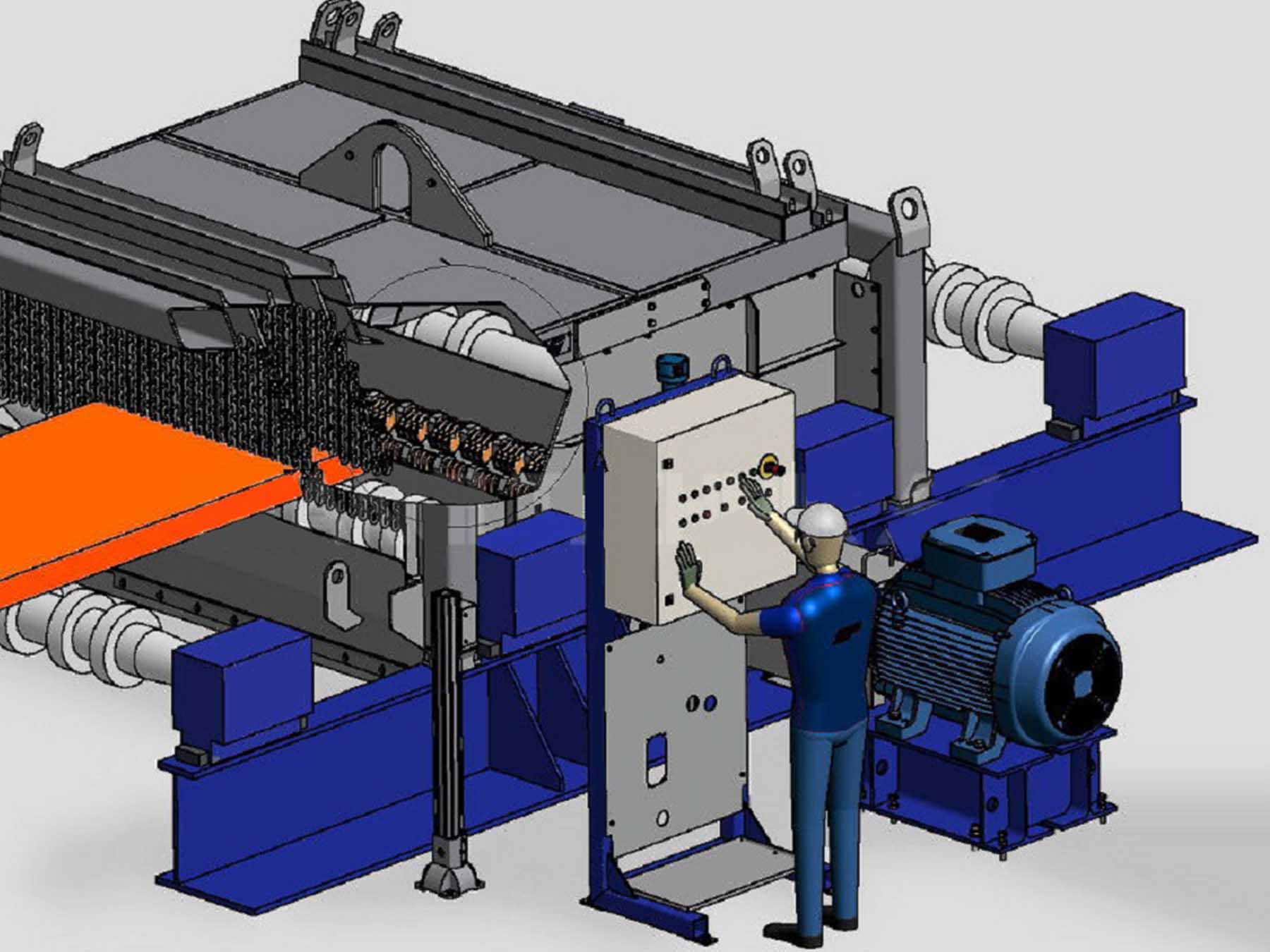

DeBu - deburring machines from Berger Engineering

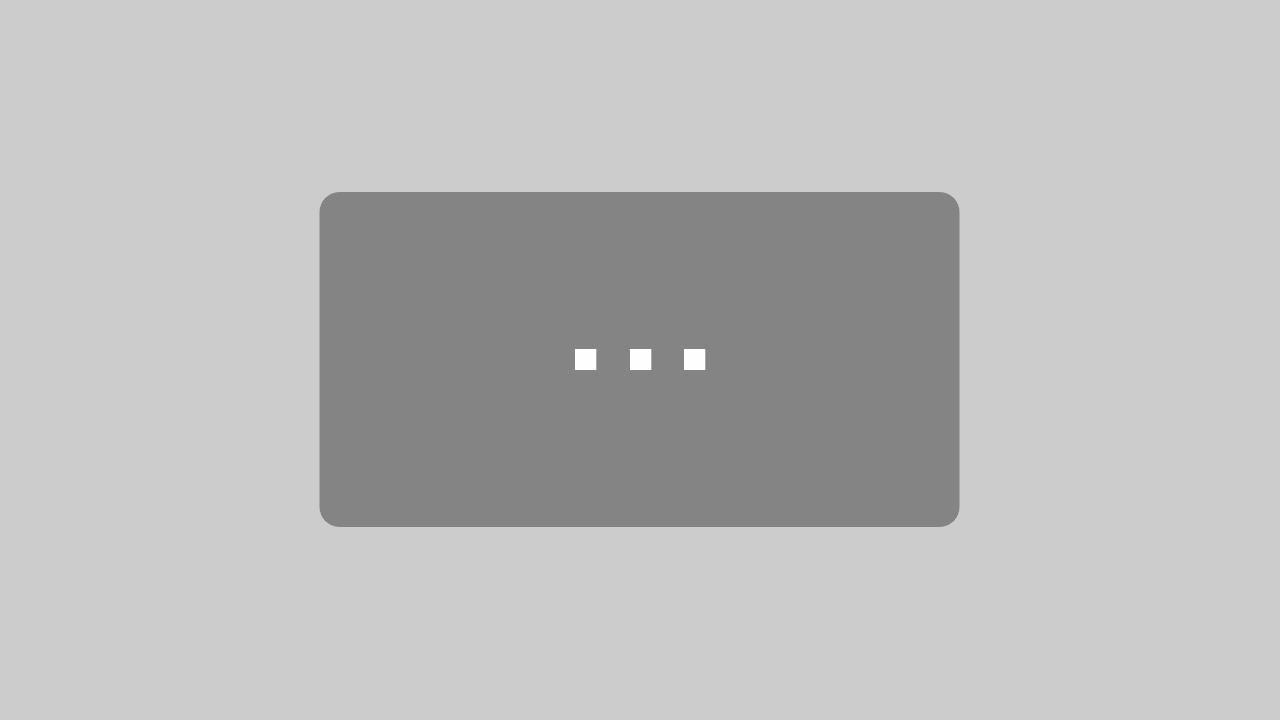

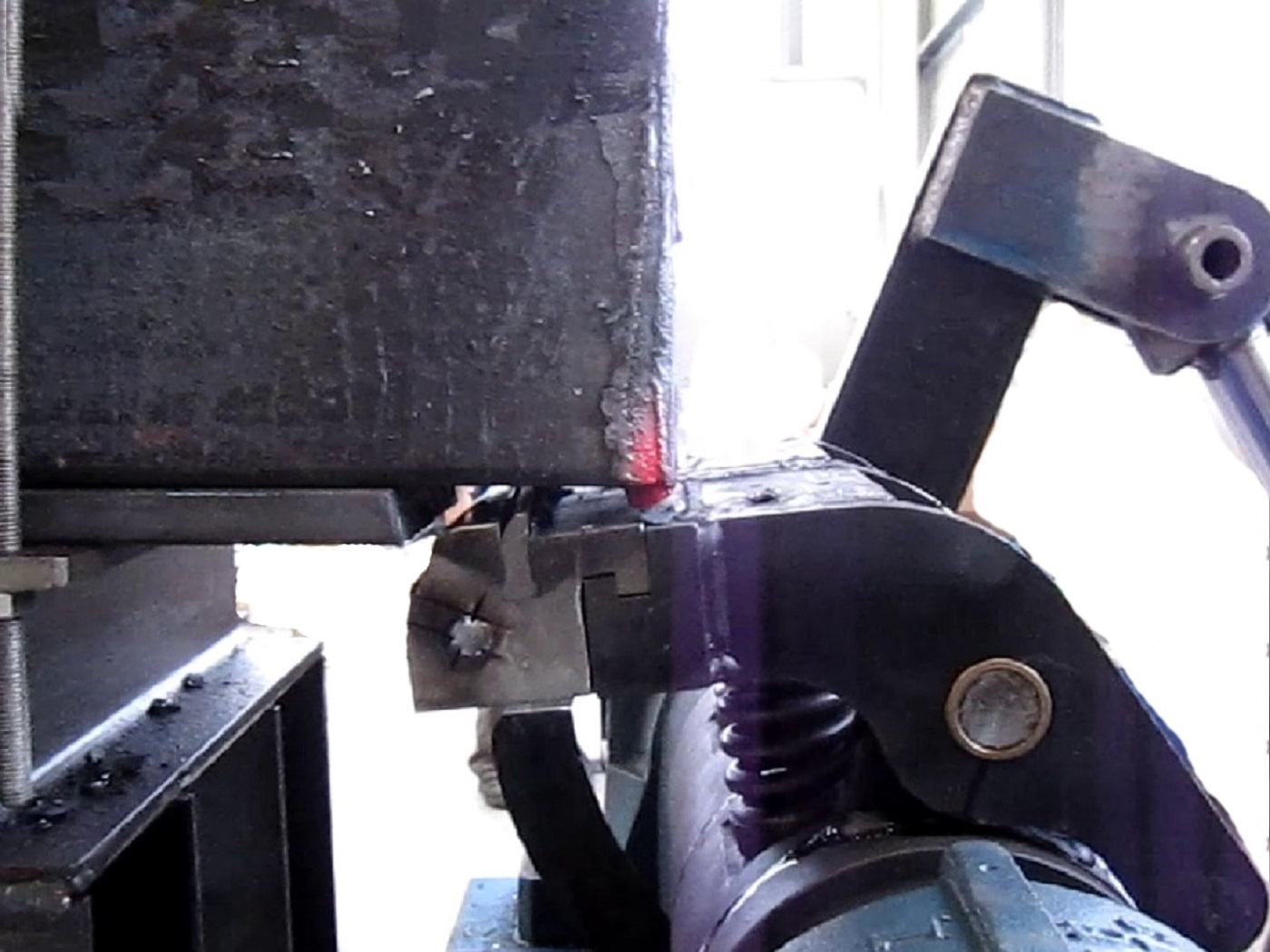

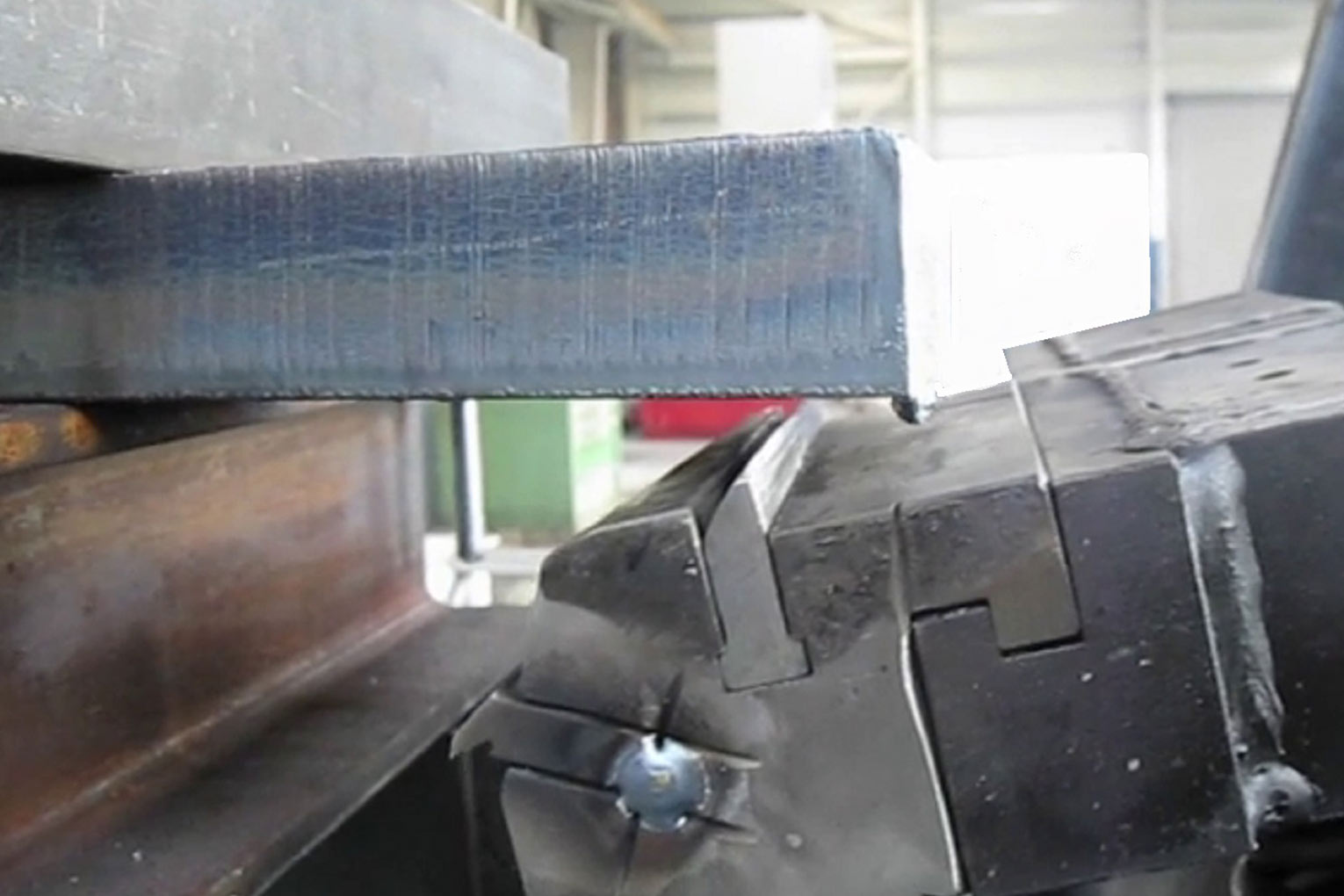

The DeBu deburring machine removes the “burr” or “beard” that was created during flame cutting. This work process runs in a continuous process and can also be carried out in parallel with several continuous casting lines (billets).

For slabs and blooms, but also for special profile girders, only individual deburring machines, DeBu’s, are normally used.

Technical parameters:

- Temperature: 20°C to 1,050°C

- Deburring rate: 98.5 – 100% (depending on temperature and speed)

- Number of machines: 1 – 9 (machines connected in parallel)

- Production speed: max.0.5 m/s – 0.75 m/s (depending on the product)

REQUEST A BROCHURE

For more information about this product, please contact us personally or request our product brochure.